Concrete-Devouring Robots Recycle Entire Demolished Buildings

Is this the key to continued urban redevelopment?

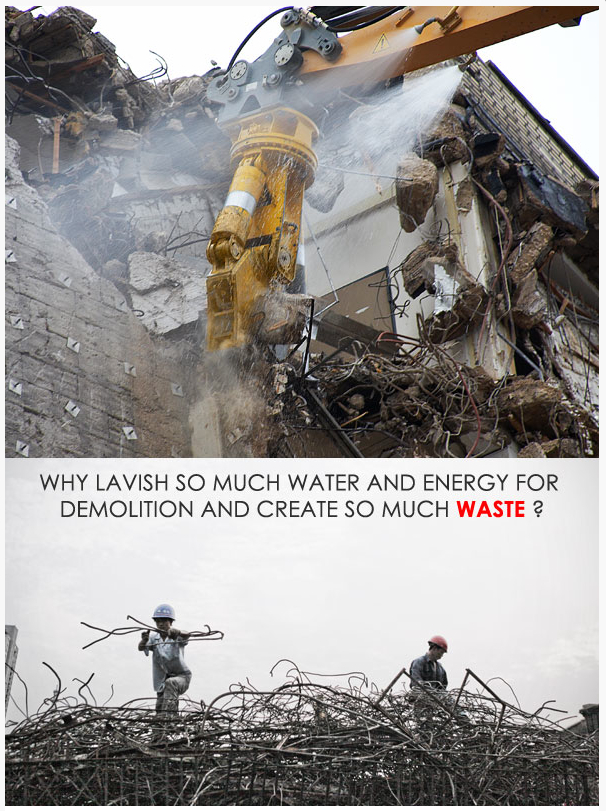

The perpetual re-creation of urbanscapes amounts to copious waste. It's true that an abundance of recycling processes aims at diminishing resource use. However, they're often heavy on the energy consumption front.

Consequently, designer Omer Haciomeroglu, in conjunction with Atlas Copco, has come up with 'ERO: Concrete De-Construction Robot'. It's programmed to pull apart reinforced concrete structures, so that they can be re-used in the construction of pre-fabricated concrete buildings.

'Today, operators manually control different sized demolition machines to smash and crash the concrete structure into dusty bits within the demolition location,' Haciomeroglu explains. 'All of these machines consume a lot of energy to operate. Water has to be sprayed constantly over the pulverised surfaces with fire hoses to prevent harmful dust from spreading around. After the work is done, big machines come and scoop the rebar and concrete mixture and transfer them to the recycle stations outside the city. There, the waste needs to be separated manually.'

So, Haciomeroglu designed ERO to separate materials during the de-construction process, achieved through Hydro-demolition and Centrifugal Decanter technologies. This means that new concrete blocks can be created onsite.

In the 2013 International Design Excellence Award (IDEA), ERO won First Prize in the Student Designs category. Haciomeroglu has studied design at California State University, Istanbul Technical University and the Umea Institute of Design, Sweden. 'As a developing designer I always look forward to being part of design teams that develop projects, concepts and products that will grant us, the humankind, valuable and entertaining vision of a better and sustainable future,' he explains.

[via PSFK]